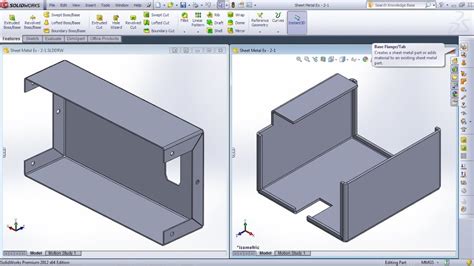

solidworks convert box to sheet metal You can create a sheet metal part by converting a solid or surface body using . In this guide, we're diving deep into the art of flux core welding, breaking down the process step by step. Whether you're a greenhorn or a seasoned welder, this guide is your ticket to unlocking the secrets of mastering flux core welding, especially when dealing with delicate 22-gauge sheet metal.

0 · zinc plated steel solidworks material

1 · solidworks sheet metal pdf

2 · solidworks convert to sheetmetal

3 · sheet metal in solidworks 2021

4 · sheet metal command in solidworks

5 · rip solidworks

6 · rip sketches

7 · how to sheet metal solidworks

westernelectricwesternelectricwesternelectricwesternelectricwesternelectricwesternelectricwesternelectricwesternelectricwesternelectricwesternelectric .

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. To convert a solid part to a sheet metal part: Create the solid part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > .Relief Type: Select the type of relief cut to be added: Rectangular; Obround; Tear; .You can create a sheet metal part by converting a solid or surface body using .You can create a sheet metal part by converting a solid or surface body using .

Use the Convert To Sheet Metal PropertyManager to convert a solid or . How to use the Convert to Sheet metal feature in Solidworks Sheet Metal.

This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal.

You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features .You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features .Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. To open this . By converting a solid part to sheet metal within SOLIDWORKS, you can simulate these fabrication processes, ensuring the part can be manufactured accurately and efficiently.

The SOLIDWORKS Convert to Sheet Metal command is an efficient way to create Sheet Metal geometry without having to be proficient in using Sheet Metal features. Step 1: Here we have a solid body that I would like to convert into a sheet metal box then get the flat pattern to make it. Step 2: 1. If you don’t have the sheet metal tab open . Once you have a Solid Body in the shape that you want, there are a couple of ways to convert it into Sheet Metal. The method you choose will depend on the state of the Solid Body and the features you want in the Feature Tree. . SolidWorks Solid to Sheet Metal Tutorial | SolidWorks Convert to Sheet Metal | Convert Shell to Sheet Metal | Rip, Insert Bend, No Bend. This tutorial shows .

Table of Contents. 1 Getting from 3D Model to Flat Sheet Metal in Sheet Metal Fabrication. 1.0.1 How to locate the Sheet Metal toolbar:; 1.0.2 How to create a sheet metal tab:; 1.0.3 How to unfold your design:; 1.0.4 .

In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part.In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part.In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part.I have a box that can't be cut from one piece (think: simple cardboard box open at the top). I modelled the box as a generic Extruded Boss/Base, then used Shell command, then Convert to Sheet Metal, then Split (because it can't all be cut from one sheet), then add Edge Flange around the top perimeter of the box but it needs a miter on the .

If the cut feature outline isn't present on the side of the part you've selected as the Fixed Entity in Convert to Sheet Metal, it won't be transferred to the Sheet Metal part. That's also the case with countersunk and counterbored holes, convert sheet metal will transfer the outline that is on the fixed face to the sheet metal part.With sketch-based forming tools, you can create a sketch with a few parameters to stamp or form the sheet metal. Normal Cut in Tab and Slot. When you use the Tab and Slot tool, you can specify that the slot is normal to the sheet even if the tab is at an angle to the slot. Slots that are normal to are essential in the manufacturing process.42 votes, 15 comments. 59K subscribers in the SolidWorks community. ALL posts related to SOLIDWORKS are welcome. . Can you make the part using center line symmetry and just mirror body + combine after sheet metal conversion. . Try checking the override default parameters box and manually selecting a relief ReplyClick Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal. In the PropertyManager, under Sheet Metal Parameters, select the fixed face. Under Bend Edges, select the bend edges. Under Rip Sketches, select the sketch you created to .

You can also create a bounding box for any cut list item in a cut list, independent of the type of solid or sheet metal bodies in the item. The bounding box is represented by a 3D sketch and is based, by default, on the X-Y plane. Taking into consideration the bounding box's orientation, the bounding box is the smallest box in which the body .I’ve tried a few methods and SolidWorks always seems to stumble into something. I’m trying to convert this shape into Sheet Metal so I can flat pattern it and make a drawing. It’s essentially an Ellipse that’s been cut in half at a 45 degree angle. Extruded to 100mm and the piece itself is .

For example, in sheet metal parts with up and down bend directions, you can map the different bend line directions to separate layers when you export the part. To export and map bend line directions for a sheet metal part: . In the SOLIDWORKS to DXF/DWG Mapping dialog box: Assign layers to entities. Map other properties. Click OK.

Create a block with the Extruded Boss/Base tool. Make the block 50mm on all sides. Shell the block to 1mm so the part is of uniform thickness. In Faces to Remove, select the faces as shown.. To bend the part, rip the block between the edges of the tabs by clicking Rip or Insert > Sheet Metal > Rip.Select the edge to rip as shown.

ALL posts related to SOLIDWORKS are welcome. Share what you know. Learn what you don't. 100% Pirate Free Sub. Zero Tolerance

Properties specific to sheet metal parts are calculated and displayed in the Cut-List Properties dialog box. Linking Materials and Sheet Metal Parameters. When you assign a custom material to a sheet metal part, you can link the sheet metal parameters to the material. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy .In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part. The software automatically selects the edges on which rips are applied.

Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. . 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and .

electric company transformer junction box

Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. . 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and .You can create a multibody sheet metal part from multiple sheet metal bodies or a combination of sheet metal bodies and and other bodies such as weldments. To create a multibody sheet metal part: Create new bodies in an existing sheet metal part using Base Flange, Convert to Sheet Metal, Insert Bends, and Lofted-Bend commands.Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal. In the PropertyManager, under Sheet Metal Parameters, select the fixed face. Under Bend Edges, click Collect All Bends.Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic .

zinc plated steel solidworks material

I'm trying to convert a loft into a sheet metal part to be flattened. The part is attached below. Any suggestions? Thought about exporting to a STEP and then bringing it back in but no luck unless I'm missing a step. The project is for a mixer blade. I used loft because I know the beginning and ending location of the part on each plain. See more at: http://www.goengineer.com/products/solidworks/Learn about the new capability in SOLIDWORKS 2019 to link the Sheet Metal Parameters to .In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part. Step 4: Set sheet metal parameters. Under Sheet Metal Parameters: a. Select a face as the fixed face for the sheet metal part. b. Set the sheet thickness and default bend radius. c. Select Keep body if you want to keep the solid body to use in another Convert to Sheet Metal feature. When cleared, the body is consumed by the Convert to Sheet .

It is possible to create a solid part, then convert it to sheet metal to add the bends and sheet metal features. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to our documentation team.

solidworks sheet metal pdf

To braze weld thin metal, you need to use a low-temperature brazing rod and a propane torch. First, clean the area with a wire brush or sandpaper to remove any dirt or rust. Then, heat the area with the torch until it reaches the .

solidworks convert box to sheet metal|zinc plated steel solidworks material