how to make a sheet metal box with curved edges Grooved Seams are a great way to join two pieces of sheet metal, but they also create tremendous strength perpendicular to the joint. A properly grooved hem has 2 broken edges, and 4 layers of sheet metal in one spot. Why Should I Have an Electrician Install My Junction Boxes? As with all electrical work, you should always call a licensed electrician to ensure things are done properly, according to code, and with safety ensured.

0 · sheet metal box steps

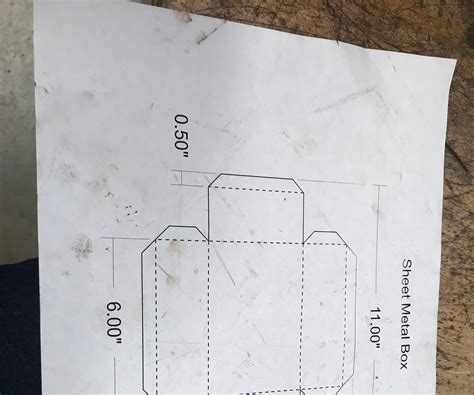

1 · sheet metal box patterns

2 · sheet metal box layout

3 · sheet metal box design template

4 · how to make sheet metal boxes

5 · how to cut sheet metal box

6 · how to bend sheet metal box

7 · flat sheet metal box pattern

Check if your switch, fixture, metal, or plastic box has its own ground wires and if not, you may need a grounding nut. You can splice device wires together in a pigtail or connect them to the ground wire of your circuit box.

This week we needed a custom sheet steel box with rounded edges similar to an electrical box.In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my . How To Bend Sheet Metal Without A Brake: How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools. .more. Fabrication Tips Making radius rounded edge. Learn some basic metal working techniques on how to make perfect round corners and radius edges.

Grooved Seams are a great way to join two pieces of sheet metal, but they also create tremendous strength perpendicular to the joint. A properly grooved hem has 2 broken edges, and 4 layers of sheet metal in one spot.

To fabricate a sheet metal box, you will need a sheet metal of your desired thickness, a metal shear or snips, a metal brake, a drill press or hand drill, a deburring tool, a tape measure, a square, and safety equipment such as .As a simple additional improvement, I would recommend folding the edges that face out, so the exposed parts are always a fold. Makes the exposed edges smooth and not sharp. Learn how to create a curved drip edge including a 180 degree hem using two bending tools from Freund - the Radius Roller 25 Edge Bender and the Single Disk . Sheetmetals are almost in every machine within a many different form. Bended, Formd etc. Almost all of them have flanges which are mostly in the form linear .

In this video, we show you how with integrated 2D and 3D sketching, Solid Edge synchronous technology allows you to perform your sheet metal design easily an. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----. In this tutorial, you'll learn how to create realistic looking photo quality images in Solid Edge. We will apply materials to parts of the model, add a backg. If so, it is good practice to create a sheet metal style and not just uncheck use thickness from rule and alter the thickness. Instead use the pencil icon and create sheet metal default for your company thickness. That way you have a dedicated style for each thickness of material and can control relief shapes and bend rads per thickness.

why does my house have a metallic smell

I am facing issue of of 2 flange corner and edge overlapping or edge seam in fusion 360 sheet metal. I am currently using Creo 2.0 where we have edge treatment option to control the overlap of the edges and also have option to make corner relief as zero. Will you please tell me how to make such parts in sheet metal of fusion 360So I'm doing this as a sheet metal part, so that I can flatten my curved surfaces. Which is fine. I've used sheet metal parts to create corrugated boxes, etc. But I'm stuck here. The top of my pedal car is flat and tapers off in the back. That's all good. The bottom has the same taper but curves up towards the back. All good here too. Welcome to solid edge tutorial channel - Solid edge Sheet metal bend & unbend - This channel is dealing with everythings about Solid edge Beginners Tutorials.

I make decorative wind spinners for the garden, using sheet metal. Cutting w/scissors leaves sharp edges. I've used brass tape on the curved edges to cover. There HAS TO BE an easier & cheaper way ! Is there a small tool to bend the edges & flatten down? The cuts are curved, not straight. No pictures - sorry. Thanx for any help. Hi drew65uk, In the Contour Roll dialog box, change the Unroll Method to Developed Length and then enter the Length you want to end up with.. Then use the Unfold tool (not the Create Flat Pattern tool) to temporarily unfold the part. Then sketch one of your slots, and use the Cut tool to create it. Then use the Rectangular Pattern tool to place the rest of the slots.machine designed to bend sheet metal to form edges and prepare the metal for wired edge. Seam can also be formed on this machine. . raised curved sections used to give additional rigidity to cylindrical sheet metal objects. . machine designed to bend all four sides of the sheet metal box. Cornice Brake. machine capable of forming sheet .

Learn Fusion 360 Sheet Metal in 20 minutes, with this crash-course for beginners. Thanks to our wonderful friends at SendCutSend.com for providing FAST and a.

"I am designing a sheet metal cover that has a constant curve from left to right but around all four edges I need to have a hem bend. . You may be able to create a forming tool for the curved edges. Juan Esteban Paz (JEPaz) Answered on 5 Oct, 2011 09:32 PM After watching this video, you'll be able to work faster and more efficiently in SOLIDWORKS Sheet Metal.To see more SOLIDWORKS tips, please visit: https://tr. Sheet metal is a thin, flat piece of metal formed during an industrial process that is used for many everyday applications.Sheet Metal Box: This is a great project to make if you are new to working with sheet metal. At this point in my class all of our sheet metal projects have been very simple with, at most, one bend. . The hems will be located on the top .

solid edge sheet metal tutorial.solid edge tutorial and free training videos for beginners.solid edge sheet metal flatten tutorials.how to flat sheet metal p. Sheet Metal for curved part Hi all, I'm trying to get sheetmetal drawing from part created with swept blend feature. The trouble I'm having is to use edge rip tool to split the curve. The part I would like to make is attached here. I have tried a simpler pyramid shape (square top square bot) and was successful in making the sheetmetal. .How to close the edges in a sheet metal box? Hello I am wondering if there is a way to close the distance between sides on a sheet metal box? I’ve tried adjusting the thickness but nothing seems to work Share Add a Comment. Sort by: Best. Open comment sort options. Best. Top. New .

sheet metal box steps

sheet metal box patterns

We often get asked if CORE EDGE Flexible Steel Edging can be formed into right angles for various applications: so we made a short video showing exactly how .Create Flange along Edge or Edge Loop . You can add a sheet metal face and bend connected to an existing sheet metal face with a specified angle. When you create the flange, the flange previews along the edge you select using default parameters. . The More panel of the Flange dialog box provides additional ways to specify flange width. On the .allowance for a wire edge is 2 1/2 times the diameter of the wire used As an example, you are using wire that has a diameter of 1/8 inch. Multiply 1/8 by 2 1/2 and your answer will be 5/16 inch, which you will allow when laying out sheet metal for making the wire edge. Joints. The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used .

Sheet Metal Box. comments sorted by Best Top New Controversial Q&A Add a Comment. Repulsive_Meet5804 . As a simple additional improvement, I would recommend folding the edges that face out, so the exposed parts are always .This video was create by BYU-Idaho for the ME 280 Mechanical Design course and demonstrates how an edge flange in the SolidWorks Sheet Metal module can be ed.

Rounded sheet metal corners are safer for assembly workers and end users handling the metal, as rough and sharp edges can cause injury. Smooth edges protect against cuts and other injuries, which every manufacturer wants to avoid. . Curved corners can more effectively withstand deformation than sharp ones, making the workpiece less likely to . 2. start with a Box, and use solid Fillet to add the corners: create a box: then invoke Fillet from the modeling menu, and choose two edges: type in the radius you want, or drag the blue arrow: then click OK. Start the Fillet command again, pick the other two edges, and use a different radius: Both methods will end up with similar results:

wild style metal brackets braces

Why is There Condensation in My Electrical Panel? There are two main reasons why condensation occurs inside electrical panels. Condensation is caused by the equipment .

how to make a sheet metal box with curved edges|how to cut sheet metal box