cnc machine control unit pdf Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. 2. State the objectives, advantages, and special requirements concerning CNC use. . Ceramic braces are similar to traditional metal braces, except they have clear or .

0 · schematic diagram of cnc machine

1 · explain Mcu in cnc

2 · diagram of cnc lathe machine

3 · cnc machine tool control systems

4 · cnc machine control unit diagram

5 · cnc lathe parts diagram

6 · block diagram of nc machine

7 · block diagram of cnc machine

There are various types of corrugated metal roofing available in the market, including galvanized, aluminum, stainless steel, painted, and copper. Each type of corrugated metal roofing has its unique features, advantages, installation process, and maintenance requirements.

cnc machines in bangalore

schematic diagram of cnc machine

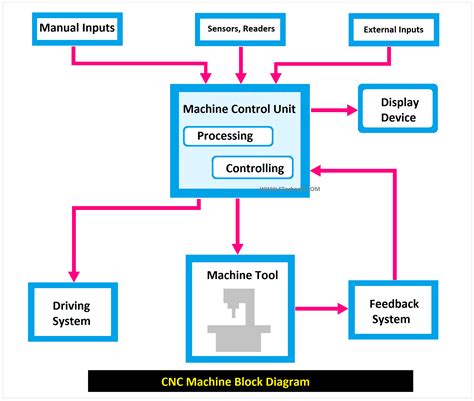

Machine Control Unit The machine control unit (MCU) is a microcomputer that stores the program and executes the commands into actions by the machine tool. The MCU consists of two main .Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. 2. State the objectives, advantages, and special requirements concerning CNC use. .4. Computer Numerical Control (CNC) Computer numerical control (CNC) is the numerical control system in which a dedicated computer is built into the control to perform basic and advanced .

explain Mcu in cnc

CNC Overview A numerical control, or “NC”, system automatically controls many machine functions and movements traditionally performed by skilled machinists. Numerical control .

CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors• classify the various types of CNC machines, • recognize the advantages and limitations of CNC machines, and • define tool handling systems and their uses in CNC machining operations. .

The machine control unit (MCU) is the heart of a NC and CNC system. It is used to perform the following functions: There are three types of MCU. Housed MCU: This MC you may be .CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors

A typical CNC machine control unit (MCU) has a number of units present inside to do all these functions. An example of sub systems that are present in an MCU are shown inMachine Control Unit The machine control unit (MCU) is a microcomputer that stores the program and executes the commands into actions by the machine tool. The MCU consists of two main units: the data processing unit (DPU) and the control .Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. 2. State the objectives, advantages, and special requirements concerning CNC use. 3. Identify the different media used to input and store CNC programs. 4. Describe the two different punched-tape formats used with CNC machines. 1.2 INTRODUCTION CNC or computer numerical control is an NC system that employs a dedicated microcomputer as a machine control unit. The presence of a microprocessor, RAM, ROM, and input and output devices has increased the level of automation in NC systems.

4. Computer Numerical Control (CNC) Computer numerical control (CNC) is the numerical control system in which a dedicated computer is built into the control to perform basic and advanced NC functions. CNC controls are also referred to as soft-wired NC systems because most of their control functions are implemented by theCNC Overview A numerical control, or “NC”, system automatically controls many machine functions and movements traditionally performed by skilled machinists. Numerical control developed to meet the requirements of high production rates, uniformity, and .CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors• classify the various types of CNC machines, • recognize the advantages and limitations of CNC machines, and • define tool handling systems and their uses in CNC machining operations. SAQ 1 (a) Define the term NC, CNC, DNC, and distributed numerical control. (b) What is BLU, and how it is related to a CNC system? 5.2 CNC OPERATIONS

The machine control unit (MCU) is the heart of a NC and CNC system. It is used to perform the following functions: There are three types of MCU. Housed MCU: This MC you may be generally house in a separate cabinet like body or may be mounted on the machine as shown in figure.CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motorsA typical CNC machine control unit (MCU) has a number of units present inside to do all these functions. An example of sub systems that are present in an MCU are shown inMachine Control Unit The machine control unit (MCU) is a microcomputer that stores the program and executes the commands into actions by the machine tool. The MCU consists of two main units: the data processing unit (DPU) and the control .

Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. 2. State the objectives, advantages, and special requirements concerning CNC use. 3. Identify the different media used to input and store CNC programs. 4. Describe the two different punched-tape formats used with CNC machines. 1.2 INTRODUCTION

CNC or computer numerical control is an NC system that employs a dedicated microcomputer as a machine control unit. The presence of a microprocessor, RAM, ROM, and input and output devices has increased the level of automation in NC systems.4. Computer Numerical Control (CNC) Computer numerical control (CNC) is the numerical control system in which a dedicated computer is built into the control to perform basic and advanced NC functions. CNC controls are also referred to as soft-wired NC systems because most of their control functions are implemented by the

CNC Overview A numerical control, or “NC”, system automatically controls many machine functions and movements traditionally performed by skilled machinists. Numerical control developed to meet the requirements of high production rates, uniformity, and .CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors• classify the various types of CNC machines, • recognize the advantages and limitations of CNC machines, and • define tool handling systems and their uses in CNC machining operations. SAQ 1 (a) Define the term NC, CNC, DNC, and distributed numerical control. (b) What is BLU, and how it is related to a CNC system? 5.2 CNC OPERATIONSThe machine control unit (MCU) is the heart of a NC and CNC system. It is used to perform the following functions: There are three types of MCU. Housed MCU: This MC you may be generally house in a separate cabinet like body or may be mounted on the machine as shown in figure.

CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors

diagram of cnc lathe machine

cnc machine tool control systems

cnc machines in san diego

cnc machines execute programs how many blocks at a time

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .

cnc machine control unit pdf|cnc machine control unit diagram