homemade wood cnc machine Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, . Order 2" x 4" x 0.25" Mild Steel Rectangle Tube A500/A513 Hot Rolled stock today on our website. Buy online with fast shipping direct to your door.

0 · make your own cnc mill

1 · make your own cnc machine

2 · do it yourself cnc machine

3 · diy woodworking cnc

4 · diy cnc machine for woodworking

5 · building your own cnc router

6 · building your own cnc machine

7 · build your own cnc mill

Your pilot-hole drill-bit size will depend on the size of your sheet metal screw. A size-4 screw should have a pilot-hole drill size of 3/32 inches; size 6, 7/64 inches; size 8, 1/8 inches; size 10, 9/64 inches; size 12, 5/32 inches; size 14 .

DIY CNC Router/Machine: How to Build Your Own. by Andreas Giencke. Updated Feb 6, 2023. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to .Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress .While purchasing a ready-made CNC machine may seem like the easiest option, building your own DIY wood CNC machine can be a rewarding and cost-effective choice. In this guide, we . Making a DIY CNC machine with limited tools. In this video, I'll show you how I built this awesome CNC router without having access to high end tools, and what it's capable of.

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, . A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to .

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be . This is how I built myself a CNC router from wood that can even machine metals!💚 Support me 💚Patreon: https://www.patreon.com/cnckitchenJoin as a YouTube m.

installing junction box oven microwave plug

Modular DIY CNC Machine: Update: Thanks everyone for the interest and support in my design! . The wood used is a mix between particle board, 2 x 4s and some other scrap wood I had laying around. The windows are from . In this video, I'll show you how I built this awesome CNC router without having access to high end tools, and what it's capable of. I decided to keep the vid. [David Taylor] needed a CNC router to do some more complex projects — so he did what any maker would do if they’re strapped for cash — make it from scratch! The impressive part of.The control system is a crucial component of a woodworking CNC machine as it determines its functionality, precision, and ease of use. When selecting a control system for your DIY CNC machine, there are several factors to consider such as compatibility with your operating system, availability of software support, and budget constraints.

Building your own DIY wood CNC machine is a rewarding journey that combines the thrill of woodworking with the precision and efficiency of CNC technology. By following this comprehensive guide, you are now equipped with the knowledge and skills to embark on this exciting project. Whether you're a hobbyist or a professional woodworker, this DIY . Is it possible to get into CNC woodworking without spending over ,000? The answer is absolutely YES! Below are a couple of links to some options that I'v.DIY CNC Carving Machine: A few years back I attempted to build a CNC machine. . I’ve been using this machine now for a couple of years for carving projects in various wood species and acrylic. 80-20 is great stuff. I had 1x1, 2x1, and 3x1 inch pieces to work with.Homemade 2'x4' Wood CNC Router: Here I am going to show how I made my CNC (Computer Numerical Controlled) router. The table measures 24"x48" and the cutting envelope is about 19”x38.” I made this CNC when I was 17 years old and .

Building this huge CNC router for woodworking from a CNC build kit was super fun. I show you how I've assembled it as well as the spoilboard setup and explai.

Hi everyone! I decided to make a spoon that matches the wood spatula I designed and made on my CNC machine. The spoon itself is a great beginner two-sided ca.

After way too long incredibly satisfying build process it's time to test the IndyMill! After finishing cable management I put my new CNC to a lot of tests wi.Hi everyone! In this video I'll tell you how I made my CNC machine for a 3D treatment and material cutting. I needed this milling machine for a new project w. Maslow CNC – Large Format DIY Wood CNC Router . MPCNC – One of the Most Versatile and Affordable Homemade CNC Machines. Price: from 2.99; Working areas: up to 48” total X & Y axis dimensions; Assembly time: 3-4 . Learn how to build your very own CNC machine with this ultimate guide for makers! This step-by-step tutorial covers everything you need to know, from choosin.

Fully cnc versions with full closed loop encoders exist of it too, about 3.5k for that, 900$ for manual version. . One can have a “milling machine” made out of wood, and still get 0.001 .

What better way to understand your machine than to assemble it yourself? Here are the best DIY and kit CNC routers on the market. All3DP; All3DP Pro; Printables Basics Buyer's Guides News Formnext 2024. More . .5-axis Milling is not an easy thing to do. I know I still need to find a robust way to zero the machine before I start cutting. Maybe add probes to make some basic homing and calibration possible. But I think overall this project was a nice and productive way of putting some really advanced CNC techniques to the test.1. CNC Plasma Cutting Machine. 2. CNC Laser Cutting Machine. 3. CNC Milling Machine. 4. CNC Router Machine. 5. CNC Lathe Machine. Although plasma & laser cutting CNC looks similar but the differences between plasma,flame and laser cutting. CNC Flame cutting machine: it is a type cutting equipment that use gas with oxygen or gasoline in metal .

Hi everyone! In this part I'll finish the assembling of the homemade CNC machine. Subscribe to the channel and put your thumbs up! Enjoy the watching!3D mode.

The FoxAlien CNC router is a device that has a 300-watt spindle and stepper motor, which makes it all the more powerful and efficient. Producing maximum moving speeds and featuring a spindle speed range with a max of 10,000, this CNC router comes with a newly designed box, control board, power supply, and emergency stop. Discover how easily you can build a powerful "Ultra-Precise" CNC Woodworking Machine --Hobby version/Desktop version/Professional wooden and/or metal base ve.

Make it as rigid as possible (for a plywood design). As to the design I came up with. This is a classic XYZ 3-axis wood cutting router. By classic I mean it has a gantry that moves along the length of the machine base (Y axis). There is a carriage that the router is mounted to that runs back and forth on the gantry (X axis). DIY Wood Lathe Upgraded Version || It's Easy To Do This || Homemade LatheThanks for watching!#lathe #woodworkingDIY Router Table for Precise Woodworking Results 20 DIY Toddler Bed Plans Free (Build DIY Kids Bed) 55 Free DIY Vanity Table Plans | DIY Makeup Vanity Ideas 2022 20 Free DIY Toddler Bed Plans (Make a DIY Floor Bed) 25 Free DIY Beehive Plans - Build Your Own Beehives 25 Free DIY Pergola Plans (Learn How To Build a Pergola) 20 Free DIY Jewelry Box Plans 15 .

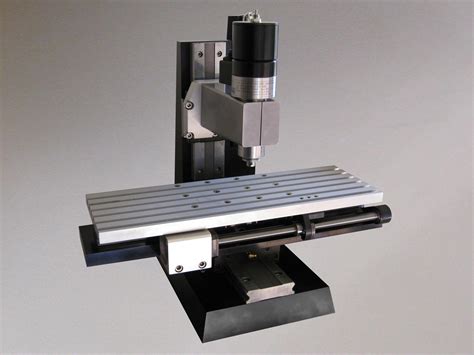

Small Engraving Cnc Milling Machine Casting Iron Frame Vmc 4020 Diy Homemade Hot Sale Wood Routers. ,500.00. Visit site. Product Details. . DIY CNC Milling Machine From Scratch. Hello everyone, well after making my first router type cnc machine on a budget ive decided to push the boat out and make a milling machine based of a sieg x3 .

I'm a pretty big fanboy of the shapeoko/carbide 3d in general, so I mostly recommend people to the shapeoko where I can. Large community, great support, known machine make it a great getting started experience. That being said, you should be fine with nearly any machine. It's a great tool to add to a woodworking shop, or a thing unto itself.

make your own cnc mill

Unlike traditional prototyping methods, CNC prototype machining offers unparalleled precision and repeatability. The process involves the removal of material from a solid block, resulting in prototypes that closely mimic the final product in terms of form and function.

homemade wood cnc machine|diy cnc machine for woodworking