sheet metal maximum thickness • "Manufacturers Standard Gauge History". Steel Market Update. Archived from the original on 2013-09-28. Retrieved 2013-06-19.• "Sheet Steel Gauges and Thicknesses" (PDF). Sheet Steel Facts. Sachiya Steel International. . See more Wells Fargo makes it easy to manage your accounts, order products, and pay bills online. Set up bill pay; Set Up Direct Deposit; Learn about Mobile banking; Open an Online Brokerage Account

0 · which thickness called sheet metal

1 · typical sheet metal thickness

2 · standard sheet metal size chart

3 · sheet metal thickness standard

4 · sheet metal thickness chart wikipedia

5 · sheet metal sizing chart

6 · most common sheet metal thickness

7 · metal sheet thickness chart

When it comes to welding thin sheet metal like car body panels, if you are not experienced and skilled enough, then you can easily create a mess as blow holes in the sheet and make the metal useless.

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or . See moreHand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The . See moreBendingThe equation for estimating the maximum bending force is,$${\displaystyle F_{\text{max}}=k{\frac {TLt^{2}}{W}}}$$,where k is a factor taking into account several parameters . See moreFasteners that are commonly used on sheet metal include: clecos, rivets, and sheet metal screws. See more

• "Manufacturers Standard Gauge History". Steel Market Update. Archived from the original on 2013-09-28. Retrieved 2013-06-19.• "Sheet Steel Gauges and Thicknesses" (PDF). Sheet Steel Facts. Sachiya Steel International. . See moreStainless steelGrade 304 is the most common of the three grades. It offers good corrosion resistance while . See more

The use of sheet metal, through a comprehensive cold working process, including bending, shearing, punching, laser cutting, water jet cutting, riveting, splicing, etc. to make the final product we want (such as computer chassis, washing machine shells, . See more• Circle grid analysis• Corrugated galvanised iron, also known as Corrugated Sheet Metal• Diamond plate• Forming limit diagram See more

which thickness called sheet metal

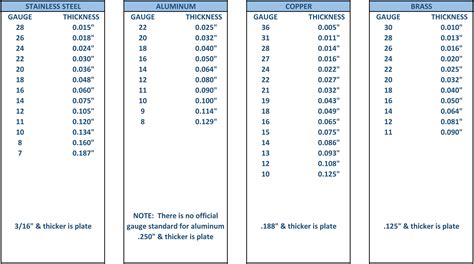

What is the Standard Thickness of Sheet Metal? In Australia, the typical thickness of sheet metal is between 0.5 millimetres and 6 millimetres. . The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the . Selecting the appropriate sheet thickness is a pivotal step in sheet metal fabrication. This choice influences a variety of factors including the part's overall strength, weight, and integral design features such as minimum bend .

Sheet metal thickness ranges from 0.024 in. (0.609mm) to 0.250 in. (6.35mm). *These thicknesses are available as Hot Rolled, Pickled & Oiled (HRPO) only. Because sheet metal .

Recommended inside bend radius for sheet metal parts should be equal to material thickness. For hard materials (Stainless steel, CRCA), an inside bend radius equal to 0.65 times of sheet thickness is also enough.Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. Factors like bend radius and feature-to-feature cut distances should be considered. . The thickness of sheet metal starts from 0.5 mm and goes up to 6 mm. Anything above that is a metal plate. The thin sheet metal is easy to form, while still providing great strength. At a relatively cheap price, it makes a great . As a general recommendation, ±0.005 in. runs right at the limit of precision flat sheet metal in a job shop environment. For bent sheet metal, variation in the raw material thickness increases the recommended precision .

By buckling the absolute maximum value is given by Euler: $$ F = \dfrac{\pi^2EI}{(kL)^2}$$ where $EI$ is the sheet's stiffness and $kL$ is the effective length (a function of the boundary conditions). The cutting speed and thickness capabilities of a laser cutter depend on several factors, including the laser power, type of metal, and material thickness. This article provides a comprehensive laser cutting thickness and .Maximum Dimensions US: Metric: Size: 39 in. x 47 in. . Sheet Metal Material Thickness Range. Because sheet metal parts are manufactured from a single sheet of metal, the part must maintain uniform wall thickness. Sheet metal .

When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger theWhat is the maximum thickness sheet metal one can reasonably bend by hand? Hi, I am trying to make a mount for a power strip on a desk out of either steel (low carbon/mild) or aluminum (6061). I will need to make a 45 degree and 90 degree bend similar to the image linked below. The plan is to screw it into the wall and attach the power strip to . Many variables are at play in how a laser cuts through a piece of metal, so the maximum laser cutting thickness depends on the specific laser and material being used, among other things. For the sake of naming a specific number, we can pair a high wattage laser — 6,000 watts — with a metal like stainless steel.

Manufacturing Process: Some manufacturing methods may have limitations on the maximum or minimum thickness they can work with. 4. Quality Standards and Testing. In order to ensure the quality of sheet metal products, China also follows various testing standards and certifications. . When it comes to sheet metal thickness in China, adhering to .

Too much zinc can lead to flaking The specifications for hot-dip galvanizing do not set a maximum coating thickness, so there is no limit on the thickness of the hot-dip galvanized coating. . Sheet metal parts cool very quickly so they dont usually experience this type of flaking but thick beams and poles can be very susceptible to flaking .

As a general recommendation, ±0.005 in. runs right at the limit of precision flat sheet metal in a job shop environment. For bent sheet metal, variation in the raw material thickness increases the recommended precision to ±0.010 in. per bend. Layout Method for Sheet Metal “Sheet metal stretches when it bends” is an oversimplification. Giuliano G, Polini W. Formability and thickness uniformity improvement in sheet metal stretching using a sheet of variable thickness. J Manuf Techn Res 2020; 12: 153–160. Google Scholar1. The maximum cutting thickness of different materials by 500W fiber laser cutting machine: the maximum thickness of carbon steel is 6mm; the maximum thickness of stainless steel is 3mm; the maximum thickness of aluminum plate is 2mm; the maximum thickness of copper plate is 2mm; 2.

Hi Friends, What is the minimum sheet metal thickness for doing a thread tapping inside a drilled hole, which has to bear hanging loads? I am designing a mounting bracket made of 304 Stainless steel sheet of 3mm thickness. Is it possible to do tapping in 3mm thickness sheet, and if not self clinching nuts (PEM Nuts) are the only way. Or is there any other way to create . What is Stainless Steel Sheet Metal Thickness? Definition and Importance; Stainless steel sheet metal thickness refers to the distance between the two surfaces of the sheet. This measurement is critical because it directly impacts the material’s strength, flexibility, and suitability for different applications.

typical sheet metal thickness

Note that the term ‘sheet metal’ is typically used to refer to materials that are under 3mm in thickness. Sheet metal bending processes, however, can be used on materials that are as thick as 20mm. . As mentioned, presses have a maximum tonnage capacity, and it may be worth checking that it will be possible to perform the bends you need .

witfib. -I his means th;lt any standard nominal thickness ( see Table J ) less than the maximum thickness specified in this table is available f& the particular length-width combination. For example. for a length-width combination of 12 500x I 600 mm, 40 mm is; Ihe maximum standard nomical thickness specified. By this, it should be understood The laws of physics must be maintained, even with sheet metal deformation. A unit of material must maintain a constant volume before, during and after forming. This allows calculation of the thickness strain (et), as the .expensive sheet metal, slow, very high formability Technology – a brief review Forming Speed 20-1000pts/hr . Yielding at maximum distortion strain energy Effective stress (in principal directions): Effective stress (in principal directions): . T = Sheet Thickness W = Width of Die Opening L = Total length of bend (into the page)

It is recommended that the diameter of the hole should be equal or more than the thickness of the sheet metal. Maximum Embossment Depth. . by the material’s thickness and ability to stretch in addition to the emboss geometry.It is recommended that the maximum depth of embossment be less than or equal to three times material thickness.Sheet metal properties You can modify the thickness, inner radius, and K-factor of sheet metal components in the Properties panel. Modifying the component's properties affects all the objects in the component. Modified property values appear in bold. You can set the default values for sheet metal components by setting sheet metal options. Delete a modified property value to .

Because Sheet Metal parts are manufactured from a single sheet of metal the part must maintain a uniform wall thickness. Sheet metal parts with a minimum of 0.9mm to 20mm in thickness can be manufactured. Hole Diameter. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Bends. Bends in .The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. 1. Wall thickness. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. Generally capabilities of of 0.9mm – 20mm . We account for +/- 0.02” bend to bend, with a maximum allowable tolerance of +/- 0.03”—the maximum cumulative tolerance of a part with multiple formed features. Sheet Metal Part Design for Manufacturing Tip . Sheet metal thickness often has slight variations compared to its stated gauge thickness. For example, a 16-gauge cold-rolled .Question: 4. A cup is being drawn from a sheet metal that has a normal anisotropy of 3. Estimate the maximum ratio of cup height to cup diameter that can successfully be drawn in a single draw. Assume that the thickness of the sheet throughout the cup remains the .

Thickness:0.3mm-10mm Size:≤1.5×3m Hole Diameter:0.8mm-100mm. Mild Steel Perforated Panels with Round Hole Punching Style. Machines for Making of Perforated Metal Panels: Metal plate is punched by the expanded metal machine in certain size of panels, and form perforated mesh with different hole shape.The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part. Beyond this limit, the results are not guaranteed to work. You can check the MRC in Tools > Evaluate > Check. In the Check Entity dialog box, under Check for, select Minimum radius of curvature and click Check. A 20-amp plasma cutter can handle a thickness of 0.125 inches, while a 30-amp plasma cutter will take on a 0.375-inch-thick metal sheet. And the maximum thickness capacity of a 100-amp plasma cutter is 1.5 inches. What Metals Cannot Be Cut With A Plasma Cutter? You’re probably already aware that a plasma cutter cannot cut plastic and wood.

Introduction. Welding is a primary process in sheet metal fabrication, characterized by high labor intensity and harsh working conditions.As such, high proficiency is essential. Automation in welding and the development of innovative joining methods have been consistent focal points for professionals in welding technology.. A pivotal aspect of welding automation is .

elgin sheet metal products

standard sheet metal size chart

Check out our western electric box selection for the very best in unique or custom, handmade pieces from our jewelry boxes shops.

sheet metal maximum thickness|sheet metal thickness standard