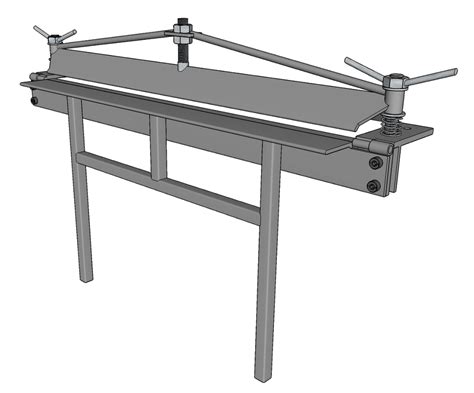

diy sheet metal brake: no welding In this project, you’ll learn how to make your own DIY sheet metal bending brake. One great thing about it is that you don’t need to weld the pieces together. You’ll only need a few easy-to-find materials, plus the instructions .

With WAGO Alu-Plus Contact Paste (20 ml syringe), solid aluminum conductors up to 4 mm² can also be connected with WAGO's 2273 Series PUSH WIRE® Junction Box Connectors and 222 Series Splicing Connectors up to 4 mm² per the standards.

0 · sheet metal brakes no welding required

1 · sheet metal brake repair

2 · sheet metal brake problems

3 · sheet metal brake no welding instructions

4 · sheet metal brake design

5 · sheet metal brake construction

6 · sheet metal brake build no welding

7 · sheet metal brake bend

Welding sheet metal with TIG welding is very good when welding without filler wire, also called autogenous TIG Welding. TIG without filler requires less welding current compared to welding with filler and offers easy to join thin sheet metals easily.

sheet metal brakes no welding required

Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until . In this episode we build a metal brake for bending steel or aluminum. We need to make the aluminum battery box in the 1973 Datsun 240Z so this will help form.

sheet metal brake repair

I needed a sheet metal brake to fix some windows around the house. Since a reasonable price metal brake could be found in local store, it gave me an excuse .

It’s a build that any experienced hacker could whip up in an afternoon and be pumping out basic sheet metal parts by sundown, and requires no welding to boot.

I decided to make a homemade sheet metal folder to bend thin metal for fabrication projects. It was simple and cheap to make and it was built with no welder..

In this project, you’ll learn how to make your own DIY sheet metal bending brake. One great thing about it is that you don’t need to weld the pieces together. You’ll only need a few easy-to-find materials, plus the instructions .

I decided to make a homemade sheet metal folder to bend thin metal for fabrication projects. It was simple and cheap to make and it was built with no welder. Here is everything I used in this . Sheet metal brakes are machines designed to make bending thin metal into shapes for use in projects such as house siding, eaves, air conditioning ductwork, and others. This project will help you build a simple sheet metal .

I used two tutorials to create my metal brake: Simple Sheet Metal Brake: No Welding Tutorial and How to make a metal brake by I Like to Make Stuff. But because I’m a beginner and do not have fancy saws to cut metal, I .

sheet metal brake problems

This is a 4 ft version that clamps down to an existing table when in use. When I’m finished with it, I can easily hide it away in seconds. This is great for folding aluminum, steel and more. There are lots of different ways to make .Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until it's bent. In this episode we build a metal brake for bending steel or aluminum. We need to make the aluminum battery box in the 1973 Datsun 240Z so this will help form.I needed a sheet metal brake to fix some windows around the house. Since a reasonable price metal brake could be found in local store, it gave me an excuse .

It’s a build that any experienced hacker could whip up in an afternoon and be pumping out basic sheet metal parts by sundown, and requires no welding to boot.I decided to make a homemade sheet metal folder to bend thin metal for fabrication projects. It was simple and cheap to make and it was built with no welder.. In this project, you’ll learn how to make your own DIY sheet metal bending brake. One great thing about it is that you don’t need to weld the pieces together. You’ll only need a few easy-to-find materials, plus the instructions shared by .

I decided to make a homemade sheet metal folder to bend thin metal for fabrication projects. It was simple and cheap to make and it was built with no welder. Here is everything I used in this build: (x1) 1/8" x 1.5" x 1.5" x 4' Steel Angle (x1) 1/8" x 2" x 3' Steel.

Sheet metal brakes are machines designed to make bending thin metal into shapes for use in projects such as house siding, eaves, air conditioning ductwork, and others. This project will help you build a simple sheet metal brake for bending small work for those who prefer to do it yourself.

I used two tutorials to create my metal brake: Simple Sheet Metal Brake: No Welding Tutorial and How to make a metal brake by I Like to Make Stuff. But because I’m a beginner and do not have fancy saws to cut metal, I made my metal brake even simpler. This is a 4 ft version that clamps down to an existing table when in use. When I’m finished with it, I can easily hide it away in seconds. This is great for folding aluminum, steel and more. There are lots of different ways to make these tools, some of which don’t even require welding! Check it out!Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until it's bent. In this episode we build a metal brake for bending steel or aluminum. We need to make the aluminum battery box in the 1973 Datsun 240Z so this will help form.

I needed a sheet metal brake to fix some windows around the house. Since a reasonable price metal brake could be found in local store, it gave me an excuse . It’s a build that any experienced hacker could whip up in an afternoon and be pumping out basic sheet metal parts by sundown, and requires no welding to boot.

I decided to make a homemade sheet metal folder to bend thin metal for fabrication projects. It was simple and cheap to make and it was built with no welder.. In this project, you’ll learn how to make your own DIY sheet metal bending brake. One great thing about it is that you don’t need to weld the pieces together. You’ll only need a few easy-to-find materials, plus the instructions shared by .I decided to make a homemade sheet metal folder to bend thin metal for fabrication projects. It was simple and cheap to make and it was built with no welder. Here is everything I used in this build: (x1) 1/8" x 1.5" x 1.5" x 4' Steel Angle (x1) 1/8" x 2" x 3' Steel. Sheet metal brakes are machines designed to make bending thin metal into shapes for use in projects such as house siding, eaves, air conditioning ductwork, and others. This project will help you build a simple sheet metal brake for bending small work for those who prefer to do it yourself.

cnc machine pyramid

I used two tutorials to create my metal brake: Simple Sheet Metal Brake: No Welding Tutorial and How to make a metal brake by I Like to Make Stuff. But because I’m a beginner and do not have fancy saws to cut metal, I made my metal brake even simpler.

sheet metal brake no welding instructions

sheet metal brake design

sheet metal brake construction

Check Weaver Metal Fab, LLC - address, owner, company on map, company status, company age, filings, officers etc. Read and write Weaver Metal Fab, LLC reviews.

diy sheet metal brake: no welding|sheet metal brakes no welding required