cnc manufacturing vs 3d printing CNC machining and 3D printing technologies offer unique strengths to manufacturers during parts’ fabrication. Even though they are distinct, they can create similar . JB8 Series Underwater Junction Box is an universal junction box for either conduit mount or niche mount applications (up to 8 fixtures). The box is tapped for the maximum number of allowable fixtures and includes the appropriate .

0 · subtractive manufacturing 3d printing

1 · machining 3d printed parts

2 · cnc vs 3d printing

3 · cnc mill 3d printer

4 · alternatives to cnc machining

5 · 3d printing and cnc machining

6 · 3d printer vs cnc machine

7 · 3d printer and cnc machine

Current wages start between $21.10 to $46.88 per hour plus Family Health Insurance, Savings Plan, 401 (k) and Retirement plans. Please contact our office for more information regarding the current wage rates or more in-depth information regarding the breakdown, by completing the form below. * Refresh Image?

Is 3D printing or CNC machining better for your custom part applications? Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and . 3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making .Currently, two of the most popular technologies on the MakerVerse platform are CNC machining and 3D printing (also known as additive manufacturing). CNC stands for “computer numerical control” and is a subtractive method used in . CNC machining operates through subtractive manufacturing, carving a final product from a solid block or sheet, offering precision and versatility across various materials. In .

CNC machining and 3D printing technologies offer unique strengths to manufacturers during parts’ fabrication. Even though they are distinct, they can create similar .

CNC machining is a form of subtractive manufacturing, which produces parts by removing material from a larger block, that is, cutting away solid plastic or metal blocks into final parts. We offer CNC milling—3-axis . They key difference between 3D printing and CNC machining is that 3D printing is a form of additive manufacturing, whilst CNC machining is subtractive. This means CNC machining starts with a block of material (called .

enclosure distribution box

Material removal is typically faster than deposition, making machining faster than printing. However, CNC machining requires more setup times to prepare the tooling and programming. .

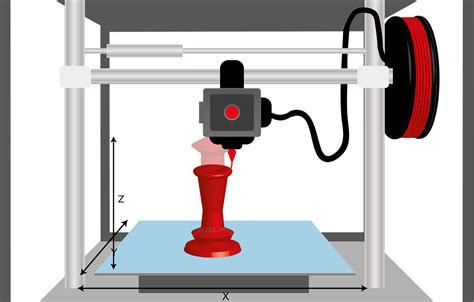

3D printing is a type of additive manufacturing, whereas CNC machining is a form of subtractive manufacturing. In simple words, CNC machining involves cutting away material from a block of . 3D printing is additive manufacturing, which means the initial material is built layer by layer, rather than removed as in subtractive manufacturing. 3D printing creates three-dimensional objects from reading a . Advantages of CNC Machining Compared to 3D Printing. The advantages of CNC machining compared to 3D printing are: CNC machining uses engineering materials and delivers the full properties of the materials, .

As others have said, the two are similar but the process of getting there can be considered the inverse of one another. The simplest way to show the difference is via examples: 3D printed Globe VS CNC 4 axis globe.Both techniques produce a similar result but .

CNC machining vs 3D printing differences. The main difference between 3D printing and CNC printing is that they work differently. 3D printing is an additive technology, while CNC is a subtractive technology. As we all know, 3D .The main difference between the two processes is that 3D printing is an additive manufacturing technique, whilst CNC machining is a subtractive manufacturing technique. This means CNC machining starts with a solid block of material (called a blank), and cuts material away from the workpiece using pre-programmed rotating tools and cutters to . Easy to implement: CNC machining is a process that can be applied to a wide variety of products and materials with little adjustment. In most cases, the only thing that may need to change between projects is the cutting tool used. Additionally, CNC machines tend to be easier to install and start using vs. 3D printers, primarily because of the machine’s design — . Conversely, a 3D printer does not start with any stock work piece, and instead adds material (usually layer by layer) until the finished part is complete. This process is known as additive manufacturing. Differences Between 3D Printing and CNC Milling. Both 3D Printing and CNC Milling are highly effective, but there are some key differences .

Exploring the pros and cons of CNC machining versus 3D printing can help manufacturers select the right technology. . In 2021, the U.S. Department of Energy (DoE) granted GE a .7 million project to investigate the design and manufacturing of 3D printed wind-turbine blades. Working with Oak Ridge National Laboratory (ORNL) and the National .This could be made on both a cnc and a 3D printer, using a STL file. because of the STL format , both machines would take hours to make the part. If you use a more CNC appropriate format the same part could be done on the CNC in less than a minute. The 3D printer would still take hours and hours and hours.

3D printing and CNC machining often find applications in different industries. Despite the rapid growth of 3D printing, CNC machining remains a mature and efficient technology. They are not necessarily interchangeable methods. Therefore, it is unlikely that 3D printing will replace CNC machining. Instead, 3D printing and CNC machining are .leading manufacturing business providing an unrivaled suite of manufacturing services from CNC machining to injection molding and 3D printing. Smoothy has worked on thousands of complex projects for customers across various industries, including aerospace and medical, working with Hitachi, Airbus, and the Imperial College of London.3D printing is easier. The only forces a printer has to overcome are the inertia of its (light weight) components. Mechanical accuracy, sufficient for 3D printing, is easily achieved. CNC mills have mich higher mechanical loads due to cutting forces, and the weight of the machine's elements. 3D Printing vs CNC Machining: Materials. Both 3D printing and CNC machining are compatible with a wide variety of materials, including both plastics and metals. 3D printing however is more focused on plastics overall, though this is changing rapidly as better an d more affordable ways of 3D printing metal are being developed by manufacturers such as 3D .

The development of stronger 3D printing materials has encouraged manufacturers across industries to explore CNC vs 3D printing, and find ways to 3D print functional parts that were previously CNC machined. The 3D printing process can save manufacturers considerable time and money, while still generating the quality necessary for industrial .Comparing CNC Machining vs. 3D Printing. The main distinction between 3D printing and CNC machining is that 3D printing is an additive manufacturing process, whereas CNC machining is subtractive. CNC machining begins with . 3D printing, as a technology, has advanced a lot since its invention by Chuck Hall in 1983. It was initially designed as a rapid prototyping method but has now grown into a true manufacturing process. 3D printing .

enclosures for electrical equipment

Since the Industrial Revolution, the world of manufacturing has come a long way. Many innovations have shaped the way parts are currently made. Today, two manufacturing methods stand out – 3D printing and CNC machining.. These two processes have dominated the manufacturing landscape, and each offers unique advantages when making custom and .

Here are some constraints to consider when deciding between additive and CNC: Geometry: The tool size in CNC machining and nozzle diameter in 3D printing dictate the minimum feature size that can be achieved. Surface Finish: CNC machines generally provide a smoother finish than 3D printers, essential for components that mate with other precision parts.

The Role of 3D Printing in Manufacturing. 3D printing, also known as additive manufacturing, plays a vital role in the manufacturing industry. It is widely used for prototyping and producing functional end-use parts, especially with plastics and metals. . CNC Machining vs. 3D Printing: Different Fabrication Methods. This article will provide an analysis of CNC vs 3D printing, highlighting their differences and how to choose from the two manufacturing methods. Unbeatable price! AnkerMake M5C 3D printer starts at only CA4.99. . 3D printing is an innovative manufacturing technology, sometimes referred to as "additive manufacturing." Similar to . Different Materials Used in 3D Printing vs Rapid Prototyping. Choosing the right materials improves the functionality and application of the final product, and this is where rapid prototyping and 3D printing diverge. With CNC prototyping, prototypes can also be made from metals like aluminum, steel, and titanium, as well as various plastics.

enclosed trailer sheet metal near me

It is a type of manufacturing that is known as additive manufacturing. This process is essentially the opposite of what CNC machining does. Rather than cutting material away from a workpiece, 3D printers are adding material layer-by-layer to build up the finished component. Metal 3D Printing vs. Metal Injection Molding – The Differences Between Additive Manufacturing & Metal Injection Molding Additive Manufacturing: What Is It, Advantages, How Does Additive Manufacturing Help Aerospace 3D Printing Vs Injection Molding – What Is The Difference Between 3D Printing And Injection Molding 3D Printing In The Toy Industry – . When 3D printing began to become more of a mainstream technology, many people crowed about how it would replace traditional manufacturing techniques, making injection molding and CNC machining .

3D printing is an additive manufacturing process that uses a 3D printer to build a three-dimensional object from a digital model. The process is highly versatile and can be used to create a wide range of products, from toys to medical implants. 3D printing is often used to create prototypes and one-off parts. . CNC Machining vs. 3D Printing .

An Overview of CNC Machining and 3D Printing. The primary difference between CNC machining and 3D printing is how they form parts and products. CNC machining is a subtractive manufacturing process, in which materials are cut or removed from a blank workpiece to shape the finished product. The Bottom Line: CNC vs. 3D Printing. From what we've seen, CNC Machining and 3D Printing overlap in some capability. Therefore, there is no one-size-fits-all solution in metal machining and manufacturing. Asking to choose among the two is like deciding what is essential between a ballpoint pen and a lead pencil.

subtractive manufacturing 3d printing

This aluminum decorative sheet with a "Union Jack" pattern is ideal for many various jobs. It enhances and repairs the appearance of numerous objects and can be used as a surface finish. It is easy to cut, fold and shape. The sheet is available in a 24" x 36" (61 cm x 91 cm) format, in a flat finish. No questions have been asked about this product.

cnc manufacturing vs 3d printing|cnc vs 3d printing