cnc machine industrial applications Explore the history, working principles, applications, benefits, and future prospects of industrial CNC machines. Learn how to choose, maintain, troubleshoot, and operate these advanced manufacturing tools safely. Some skoolie owners who have faced this problem have rebuilt the floor with a 3" steel tube frame (or strap metal in some cases which certainly isn't going to bear much weight) covered with sheet metal welded on (3" is about the height of the original floor so this brings it back to the same level).

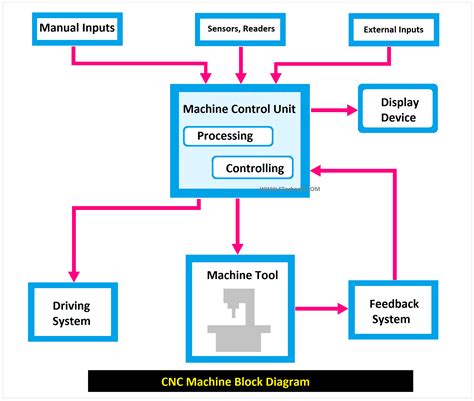

0 · schematic diagram of cnc machine

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

We needed to find out the absolute best type of glue or adhesive to use to hold these 2 different materials together. We ended up finding a guide .

laser cnc sheet metal cutting exporters

schematic diagram of cnc machine

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC machining is nothing short of a miracle for manufacturers, providing high-speed manufacturing with complete automation and ultra-high precision. The countless benefits of the CNC machining process have made it applicable in many manufacturing industries. Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

products made by milling machine

Explore the history, working principles, applications, benefits, and future prospects of industrial CNC machines. Learn how to choose, maintain, troubleshoot, and operate these advanced manufacturing tools safely.

CNC machines can handle a variety of materials (such as metal, plastic, and wood) and can machine complex geometric shapes. This flexibility makes CNC technology suitable for various industries and applications. Some typical applications of mill CNC machines include cabinets, furniture, prototype models, signage, and musical instruments. CNC milling machines offer high precision and versatility and can produce complex shapes that would be nearly impossible to achieve with manual machining.

Delve into the types and capabilities of CNC machines, empowering engineers with a comprehensive understanding of their diverse applications. This guide equips engineers to leverage CNC technology for innovative solutions across industries. CNC (Computer Numerical Control) machines have transformed manufacturing processes across industries. CNC machining is a computerized-control, automated manufacturing technique that involves custom-designed components. It utilizes equipment whose movement is controlled by pre-programmed codes and software. Modern manufacturing is crucial in industry. It makes products with great precision and accuracy.

CNC machining involves advanced technologies, programming software, and high-quality materials. Computerized tooling techniques also underpin countless industries, providing precision parts that satisfy ISO standards. Understanding the role CNC plays in the modern economy can help you innovate new products at lower costs. Computer Numerical Control (CNC) machines have revolutionized manufacturing, offering unmatched precision, efficiency, and versatility. In this article, we will delve into what CNC machines.CNC machining emerges as a beacon in this journey, offering unparalleled advantages that have transformed production processes across industries. Before we delve into the specifics, let’s set the stage by understanding why CNC machining is . CNC machining is nothing short of a miracle for manufacturers, providing high-speed manufacturing with complete automation and ultra-high precision. The countless benefits of the CNC machining process have made it applicable in many manufacturing industries.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Explore the history, working principles, applications, benefits, and future prospects of industrial CNC machines. Learn how to choose, maintain, troubleshoot, and operate these advanced manufacturing tools safely.CNC machines can handle a variety of materials (such as metal, plastic, and wood) and can machine complex geometric shapes. This flexibility makes CNC technology suitable for various industries and applications. Some typical applications of mill CNC machines include cabinets, furniture, prototype models, signage, and musical instruments. CNC milling machines offer high precision and versatility and can produce complex shapes that would be nearly impossible to achieve with manual machining.

Delve into the types and capabilities of CNC machines, empowering engineers with a comprehensive understanding of their diverse applications. This guide equips engineers to leverage CNC technology for innovative solutions across industries. CNC (Computer Numerical Control) machines have transformed manufacturing processes across industries. CNC machining is a computerized-control, automated manufacturing technique that involves custom-designed components. It utilizes equipment whose movement is controlled by pre-programmed codes and software. Modern manufacturing is crucial in industry. It makes products with great precision and accuracy.CNC machining involves advanced technologies, programming software, and high-quality materials. Computerized tooling techniques also underpin countless industries, providing precision parts that satisfy ISO standards. Understanding the role CNC plays in the modern economy can help you innovate new products at lower costs. Computer Numerical Control (CNC) machines have revolutionized manufacturing, offering unmatched precision, efficiency, and versatility. In this article, we will delve into what CNC machines.

industries that use cnc machines

different type of cnc machines

laser cutter vs cnc machine

laser cnc cut sheet metal manufacturers

The recommended thickness of acrylic around the metal Locator housing is 2mm; The combination of the Locator abutment (1mm above tissue) the locator housing and attachment (2.25mm) along with a space between the attachment & abutment to accommodate for movement (1mm) equals 4.25mm

cnc machine industrial applications|application of cnc lathe machine