cad and cnc machining Get foundational knowledge in computer-aided design (CAD), computer-aided manufacturing (CAM) and the practical use of CNC mills. Begin in Fusion CAD by learning how to read basic blueprints, how to properly sketch and model 3D parts. $11K+

0 · cnc programming simulation software

1 · cnc machining programming software

2 · cnc machining program

3 · cnc machining center software

4 · cnc machine software download

5 · cnc lathe programming software

6 · cnc lathe machine software download

7 · cam machining software

$1,999.95

Get foundational knowledge in computer-aided design (CAD), computer-aided manufacturing (CAM) and the practical use of CNC mills. Begin in Fusion CAD by learning how to read basic blueprints, how to properly sketch and model 3D parts. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are distinct yet complementary technologies in the CNC machining process. CAD focuses on creating digital 3D models of parts or .

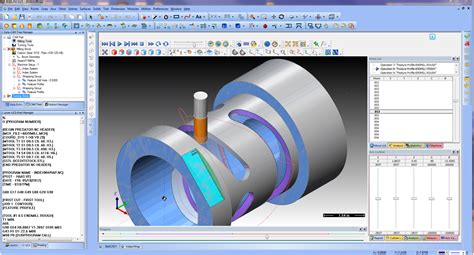

In this post, we’ll explore how CAD/CAM software revolutionizes CNC machining and why it’s a game-changer for manufacturers. Understanding CAD and CAM CAD | Designing with Precision. CAD software is used by engineers to create detailed 3D models of parts, allowing for precise visualization and design of complex geometries. It’s the first . Get foundational knowledge in computer-aided design (CAD), computer-aided manufacturing (CAM) and the practical use of CNC mills. Begin in Fusion CAD by learning how to read basic blueprints, how to properly sketch and model 3D parts. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are distinct yet complementary technologies in the CNC machining process. CAD focuses on creating digital 3D models of parts or products, while CAM translates these designs into machine-readable instructions for CNC equipment. CAD/CAM enables designers and engineers to create precise 2D and 3D models. CAM automates and controls manufacturing processes based on CAD designs. CNC technology programs and controls machine movements in the manufacturing process. The integration of CAD/CAM and CNC improves precision, efficiency, and cost-effectiveness.

cnc programming simulation software

In this post, we’ll explore how CAD/CAM software revolutionizes CNC machining and why it’s a game-changer for manufacturers. Understanding CAD and CAM CAD | Designing with Precision. CAD software is used by engineers to create detailed 3D models of parts, allowing for precise visualization and design of complex geometries. It’s the first .

buxcon sheet metal inc

CNC Machining is a subtractive manufacturing technology, where material is removed from a solid block, or workpiece, using various CNC machining equipment such as milling machines, lathes, and grinders. This process is known for its high precision and versatility in creating a wide range of materials, including metal, plastic, wood, foam, and .The CNC machining process begins with creating a 2D vector or 3D Computer-Aided Design (CAD) of a solid part. This can be done either in-house or by a CAD/CAM (Computer-Aided Manufacturing) design service company.

Dive into CAD, CAM, and PathPilot® basics for CNC beginners. Learn essential terminology and workflow steps for successful CNC machining.CAD/CAM software is used to both design a product and program manufacturing processes, specifically, CNC machining. CAM software uses the models and assemblies created in CAD software, like Fusion 360, to generate toolpaths that drive machine tools to .CNC machining is a digital manufacturing technology: it produces high-accuracy parts with excellent physical properties directly from a CAD file. Due to the high level of automation, CNC is price-competitive for both one-off custom parts and medium-volume productions.

With CAD/CAM, the CNC machines can run tests, simulate the prototype and start machining faster than ever before! Managing manufacturing projects requires a high level of visibility to maximize efficiency. CNC CAD CAM allows you . Get foundational knowledge in computer-aided design (CAD), computer-aided manufacturing (CAM) and the practical use of CNC mills. Begin in Fusion CAD by learning how to read basic blueprints, how to properly sketch and model 3D parts. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are distinct yet complementary technologies in the CNC machining process. CAD focuses on creating digital 3D models of parts or products, while CAM translates these designs into machine-readable instructions for CNC equipment. CAD/CAM enables designers and engineers to create precise 2D and 3D models. CAM automates and controls manufacturing processes based on CAD designs. CNC technology programs and controls machine movements in the manufacturing process. The integration of CAD/CAM and CNC improves precision, efficiency, and cost-effectiveness.

In this post, we’ll explore how CAD/CAM software revolutionizes CNC machining and why it’s a game-changer for manufacturers. Understanding CAD and CAM CAD | Designing with Precision. CAD software is used by engineers to create detailed 3D models of parts, allowing for precise visualization and design of complex geometries. It’s the first .CNC Machining is a subtractive manufacturing technology, where material is removed from a solid block, or workpiece, using various CNC machining equipment such as milling machines, lathes, and grinders. This process is known for its high precision and versatility in creating a wide range of materials, including metal, plastic, wood, foam, and .The CNC machining process begins with creating a 2D vector or 3D Computer-Aided Design (CAD) of a solid part. This can be done either in-house or by a CAD/CAM (Computer-Aided Manufacturing) design service company.

Dive into CAD, CAM, and PathPilot® basics for CNC beginners. Learn essential terminology and workflow steps for successful CNC machining.CAD/CAM software is used to both design a product and program manufacturing processes, specifically, CNC machining. CAM software uses the models and assemblies created in CAD software, like Fusion 360, to generate toolpaths that drive machine tools to .

CNC machining is a digital manufacturing technology: it produces high-accuracy parts with excellent physical properties directly from a CAD file. Due to the high level of automation, CNC is price-competitive for both one-off custom parts and medium-volume productions.

These regulations describe in detail the required junction box size, depending on the number and size of conductors and fittings enclosed within the box. You’ll need to calculate both box volume and box fill when determining the appropriate size for a junction box .

cad and cnc machining|cnc lathe programming software